- Home

- News

- LED Display Academy

- Flexible LED display

What is flexible LED Display? Why to use flexible LED display?

Content

- What is a Flexible LED Module?

- Flexible Yet High Rigidity.

- Copper-Mounted LED Lamps.

- More Magnets, Stronger Magnetic Force.

- Ultra-Soft Silicone Housing.

- Gold-Plated Connectors.

- High-Quality Solder Paste.

- What precautions should be taken when using flexible LED modules?

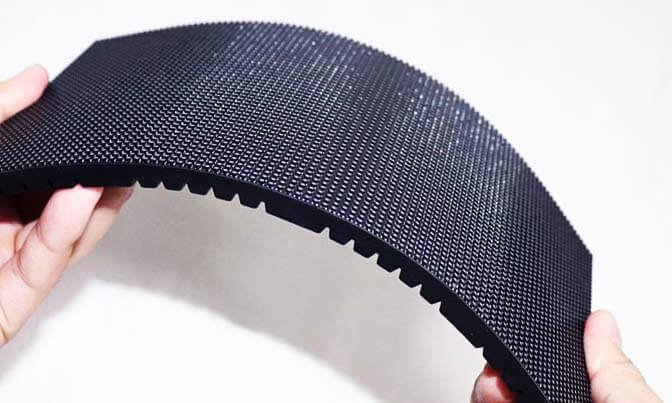

Flexible LED modules have a wide range of applications, primarily because flexible LED displays are highly flexible, capable of folding and bending, and are easy to install.

1. What is a Flexible LED Module?

Compared to traditional LED display panels, which consist of rigid PCB boards and base casings with no flexibility, rigid boards cannot be used in curved or bent areas. Alternatively, special processes like cutting corners are required, significantly increasing costs and resulting in imperfect craftsmanship.

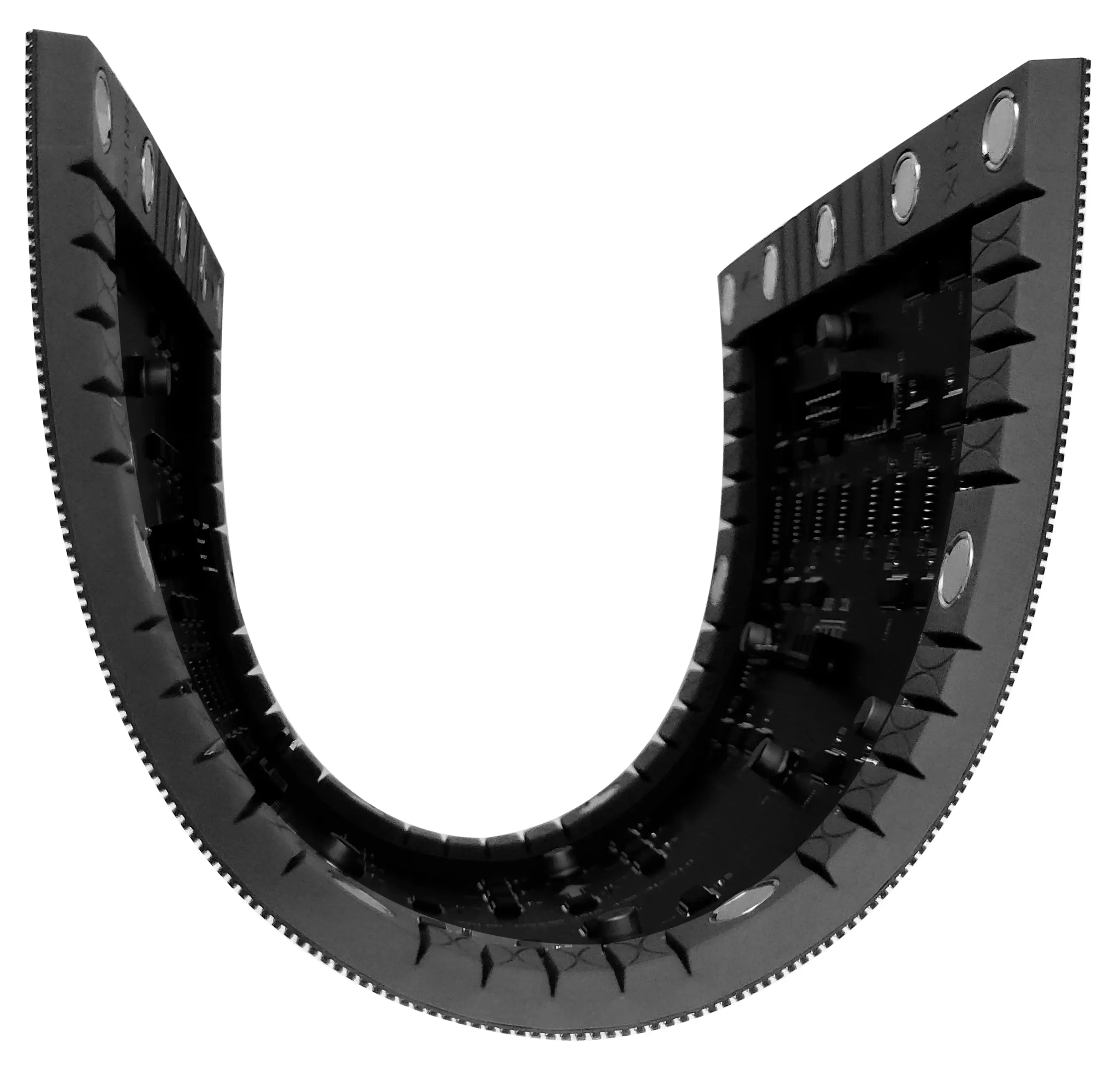

Flexible LED modules were developed specifically to address these issues. Also known as flexible LED screens or soft LED modules, these units enable the creation of displays in various shapes—such as circles, rings, strips, curved panels, and more.

While sharing the same display principle as conventional LED screens, flexible modules utilize flexible PCBs and backshells, granting them exceptional pliability that allows 120-degree folding. Specifications include P1.25, P1.5, P1.8, P2, P2.5, P3, P4, and P5.

2. Flexible Yet High Rigidity.

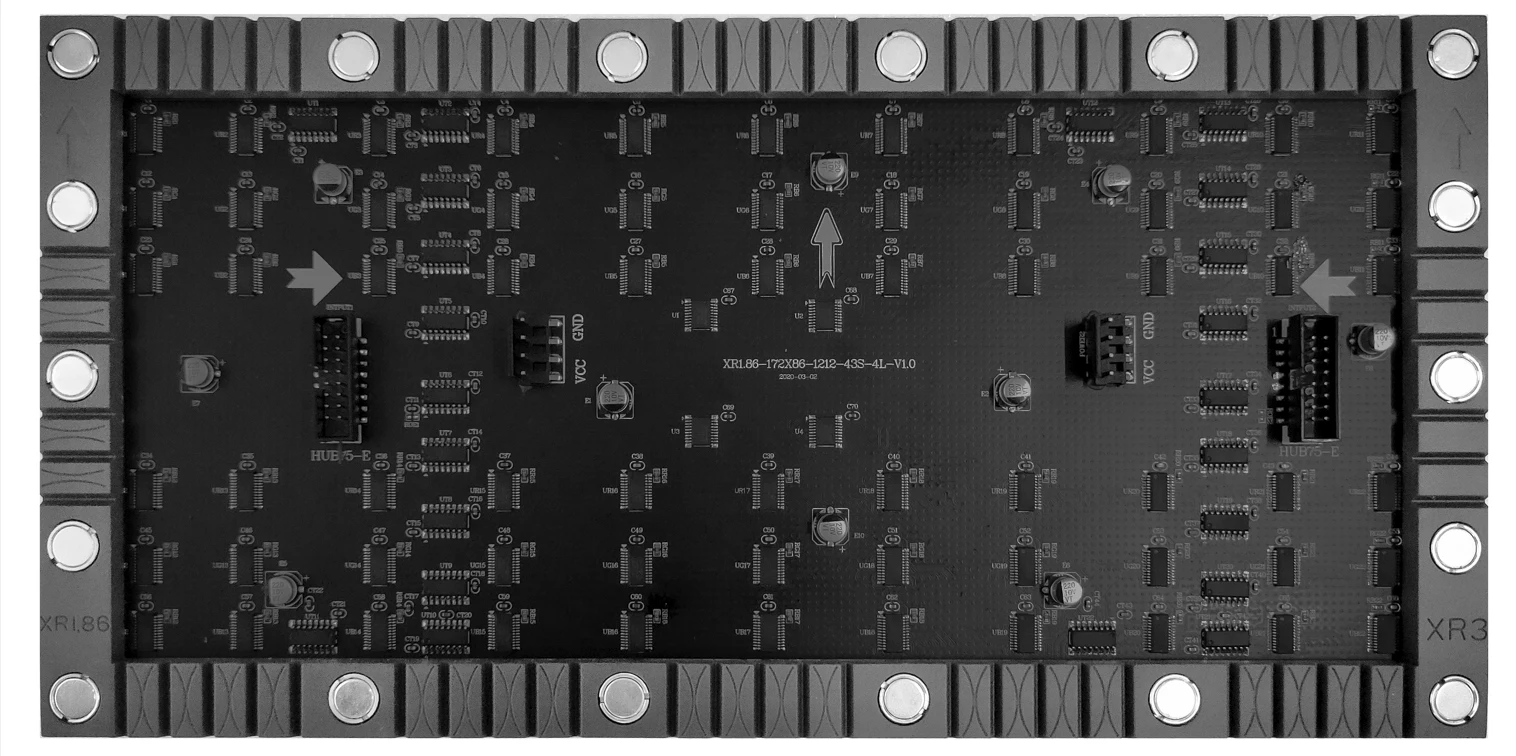

The flexible PCB circuit board, made from flexible insulating substrate material, offers high strength, compression resistance, and anti-distortion properties. The circuit board employs wave soldering technology and features a green solder mask oxygen barrier layer to prevent circuit moisture oxidation and extend service life.

3. Copper-Mounted LED Lamps.

High-quality LED chips paired with copper mounts prevent rusting due to environmental or weather conditions. Flexible LED display modules maintain stable operation even under bending deformation. They deliver high brightness with precise color output, ensuring clear, flicker-free images with vibrant, pure colors and versatile adaptability.

4. More Magnets, Stronger Magnetic Force.

The flexible module design incorporates more magnets for enhanced magnetic strength and superior adhesion. This enables smoother splicing, seamless transitions between modules and curves, reduced gaps, and superior display performance for the fully flexible LED screen panel.

5. Ultra-Soft Silicone Housing.

Features an ultra-soft silicone sleeve, providing excellent overall flexibility for the flexible LED module, allowing it to be shaped into any form. Highly flexible LED modules achieve perfect screen conformity. The soft silicone sleeve, paired with a flexible PCB board, offers a smooth, refined texture that adheres exceptionally well to the steel structures of irregularly shaped LED displays.

6. Gold-Plated Connectors.

Flexible LED modules often feature unique shapes and are deployed in complex environments, making maintenance challenging. Gold-plated connectors ensure more stable signal transmission, preventing oxidation and corrosion caused by environmental factors or humidity that could otherwise disrupt signal flow.

7. High-Quality Solder Paste.

All SMT LEDs utilize silver-containing solder paste, ensuring more secure soldering of LED pins and reducing the risk of detachment. Inferior solder paste can easily break LED pins during bending or deformation, causing open circuits and damaging LEDs on the flexible circuit board.

Flexible LED modules can create not only large-scale curved displays for indoor/outdoor use but also various curved line screens or specialty signage. Examples include strip screens, logo displays, outdoor cylindrical screens, corner displays, and other flexible LED displays. The most common applications involve using flexible LED screens to create cylindrical displays and circular LED screens for retail stores. As flexible LED module prices continue to decrease, cylindrical screens are increasingly deployed in shopping malls, hotels, airports, transportation hubs, and similar venues.

8. What precautions should be taken when using flexible LED modules?

Flexible LED modules are installed using bending techniques. Avoid exceeding the manufacturer’s specified minimum curvature range and maximum bending angle to prevent component detachment or PCB circuit breaks.

LED Display Screen Price Check

Quick and easy: Enter your specifications and get a quote in one business day