- Home

- News

- LED Display Academy

- SMD vs. COB vs. GOB: A Comprehensive Guide to LED Packaging Technologies

SMD vs. COB vs. GOB: A Comprehensive Guide to LED Packaging Technologies

Content

- What is LED Packaging Technology

- Exploring the Core Technologies: SMD, COB, and GOB

- Color Performance and Visual Quality

- Durability and Maintenance: A Balancing Act

- Conclusion

As the demand for high-definition visuals grows across industries—from corporate boardrooms to immersive retail spaces—the technology behind the LED screens is evolving rapidly. When searching for the perfect fine pixel pitch LED display, you will likely encounter three primary packaging technologies: SMD, COB, and GOB.

Understanding the differences between these technologies is crucial for making an informed investment. In this article, we will break down what LED packaging is, explore the mechanics of SMD, COB, and GOB, and help you decide which is best for your specific application.

1. What is LED Packaging Technology?

In the LED industry, “packaging” refers to the process of integrating the Light Emitting Diode (LED) chip with other components into a protective enclosure. Think of it as “LED wrapping.” It is a critical stage in the manufacturing chain because it dictates how the light is emitted, how heat is dissipated, and how well the internal components are protected from the environment.

From a professional standpoint, the choice of packaging technology significantly impacts the performance metrics of an LED screen. It determines the optical parameters (brightness and color quality), the physical durability, and the overall lifespan of the product. As we move toward the era of the fine pixel pitch LED display, packaging has become the “secret sauce” that separates standard LED screens from high-end, high-performance visual solutions.

2. Exploring the Core Technologies: SMD, COB, and GOB

What is SMD? (Surface Mounted Device)

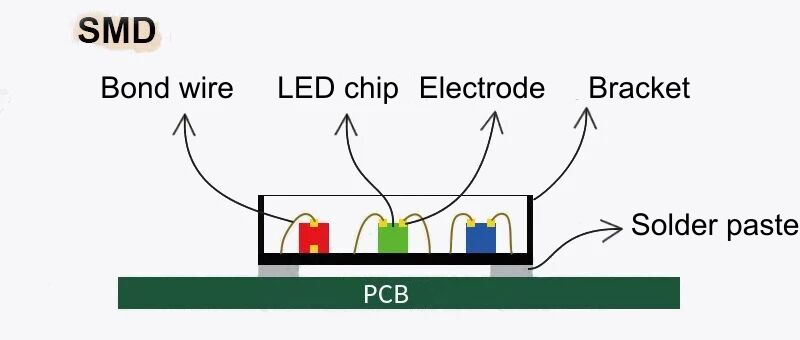

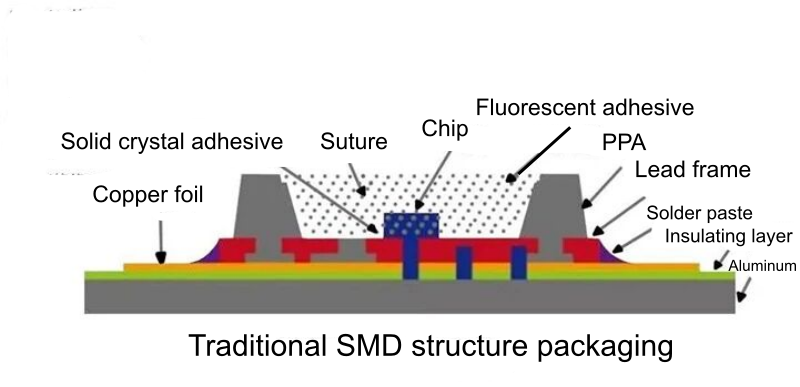

SMD, or Surface Mounted Device, is currently the most mature and widely used technology in the LED market. In SMD packaging, the LED chip, bracket, wire, and epoxy resin are integrated into a single “lamp bead.” These individual lamp beads are then soldered onto a PCB (Printed Circuit Board) using high-speed SMT (Surface Mount Technology) and reflow soldering.

Advantages of SMD:

Advantages of SMD:

- Mature Ecosystem: Because the technology has been around for decades, the supply chain is highly optimized, resulting in lower manufacturing costs.

- Color Consistency: Individual beads can be binned and sorted before assembly, ensuring excellent color uniformity across the panel.

- Ease of Repair: If a single pixel fails, a technician can easily replace the individual SMD lamp bead.

The Limitation:

However, as the industry pushes toward fine pixel pitch LED display standards (pitches below 1.0mm), SMD faces challenges. The sheer number of tiny beads makes the soldering process difficult, and the exposed lamp beads are vulnerable to damage from physical impact or moisture.

What is a COB LED Display? (Chip on Board)

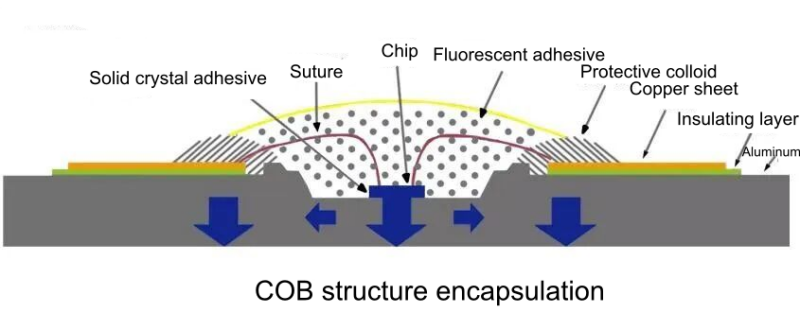

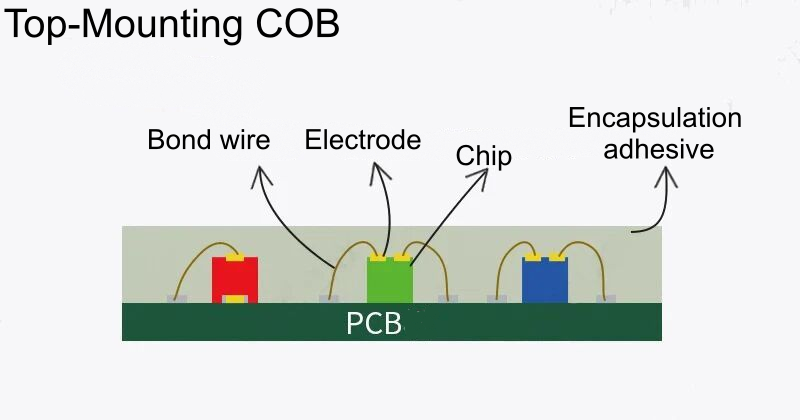

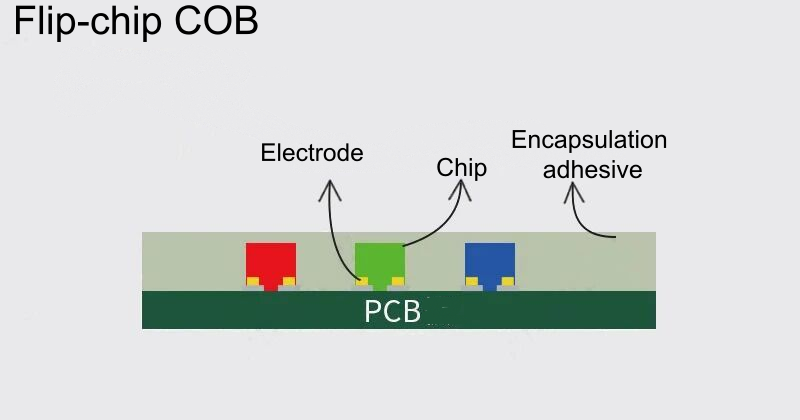

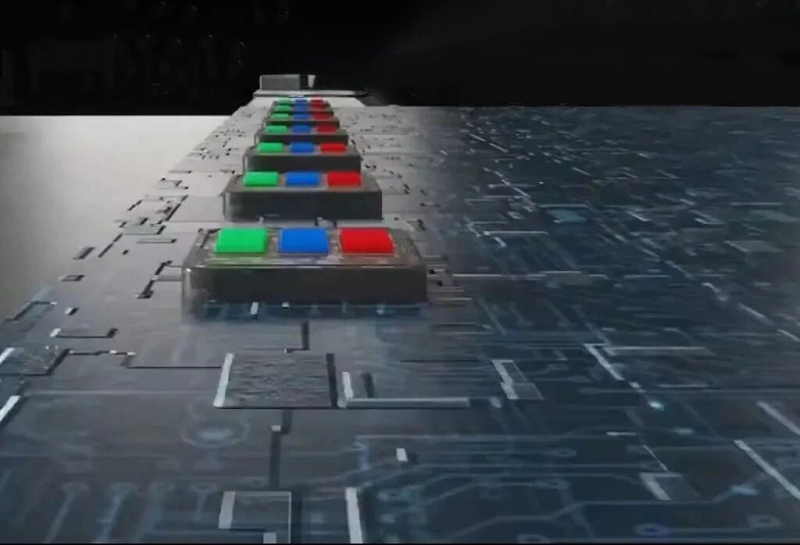

The COB LED display represents the next generation of high-density integration. Instead of packaging each chip into a bead, COB technology fixes the LED chips directly onto the PCB substrate. Once the chips are bonded and electrically connected via wire bonding, the entire module is encapsulated with a specialized resin.

The Excellence of COB:

- Ultra-Fine Pitch: By removing the bulky bracket used in SMD, COB allows for much tighter pixel spacing, making it the premier choice for a fine pixel pitch LED display.

- Superior Protection: Since the chips are sealed under a continuous resin layer, a COB LED display is inherently resistant to dust, moisture, static, and physical impact.

- Visual Comfort: COB acts as a “surface light source” rather than a “point light source.” This reduces the “LED screen door effect,” eliminates moiré patterns, and provides a much softer, more comfortable viewing experience for long-term use.

What is GOB? (Glue on Board)

GOB is an innovative “protection” technology designed to bridge the gap between SMD and COB. It starts with a standard SMD module and then applies a layer of high-transparency epoxy glue across the entire surface. This creates a “shield” or “armor” for the SMD beads.

Key Features of GOB:

- Extreme Durability: GOB LED screens are incredibly rugged. They are waterproof, dustproof, and can withstand significant physical bumps—making them ideal for the rental market where LED screens are moved frequently.

- Environmental Resistance: It protects against salt spray, oxidation, and blue light, extending the life of standard SMD modules in harsh environments.

- Trade-offs: While it offers great protection, it doesn’t solve the inherent pixel-pitch limitations of SMD, and repairing a module beneath a thick layer of glue can be challenging.

3. Color Performance and Visual Quality

When comparing these technologies, the visual output is often the deciding factor for high-end installations.

SMD: High Resolution with Some Gaps

SMD LED displays provide sharp, high-resolution images. However, at very close viewing distances, the individual pixel structure is visible. Because the LEDs are individual points of light, long-term viewing can sometimes lead to eye fatigue. There is also a slight risk of color drift or brightness decay over several years of use.

COB: The Gold Standard for Fine Detail

A COB LED display offers an unparalleled viewing experience. With a 160°+ wide viewing angle, the colors remain vivid even when viewed from the side. The integrated encapsulation provides a more uniform black level, leading to higher contrast ratios. While some COB LED screens can be reflective in high-brightness environments (due to the resin finish), modern anti-glare coatings have largely mitigated this issue. For a truly high-end fine pixel pitch LED display, COB is the industry leader in image smoothness.

GOB: Enhanced Consistency

GOB improves upon the SMD experience by using highly transparent materials that don’t interfere with color. The protective layer actually helps to diffuse light slightly, improving the viewing angle and reducing the harshness of the point light source, though it doesn’t quite reach the “surface light” quality of COB.

4. Durability and Maintenance: A Balancing Act

SMD: Easy to Fix, Hard to Protect

SMD LED screens are delicate. A simple accidental bump during installation can knock off a lamp bead. However, if a pixel does fail, maintenance is straightforward and can often be done on-site by a trained technician with a soldering iron.

COB: Built Like a Tank, Factory-Level Repair

A COB LED display is incredibly difficult to damage. It can handle being touched, wiped, or even lightly bumped without any pixel loss. This reliability drastically reduces the “dead lamp” or “caterpillar” (line of failed pixels) phenomena. However, if a failure does occur within the encapsulated layer, the module usually needs to be sent back to the manufacturer for professional repair, as it requires specialized equipment to remove the resin and replace the chip.

GOB: The Rugged Hybrid

GOB is the most durable against external forces. It is the preferred choice for mobile stages or high-traffic public areas. Like COB, repairing a GOB module is difficult because the glue layer must be removed, which can be a messy and complex process.

5. Conclusion: Which Should You Choose?

Choosing the right technology depends on your specific needs, budget, and environment:

1. Choose SMD if: You are working with a limited budget, the pixel pitch requirement is above 1.5mm, and you want an LED screen that is easy and cheap to maintain over time.

2. Choose a COB LED display if: You require a fine pixel pitch LED display (0.9mm or below) for a high-end command center, corporate boardroom, or luxury home cinema. COB is the best choice for visual comfort and long-term reliability in high-definition settings.

3. Choose GOB if: You need a durable LED screen for rental use, high-traffic retail environments, or locations where the LED screen might be exposed to moisture and physical contact, but you aren’t ready to invest in full COB technology.

Partner with Megalight LED for Your LED Display Journey

At Megalight LED, we are more than just a manufacturer; we are your partners in visual innovation. We specialize in the research, development, and production of high-performance SMD, COB, and GOB LED displays.

Whether you are looking for a state-of-the-art COB LED display or a robust fine pixel pitch LED display solution, our team provides full-spectrum support—from initial design and installation to content services and technical maintenance. We ensure that your investment delivers the maximum visual impact and the best possible return on investment.

Contact Megalight LED today to discover which LED packaging technology will bring your vision to life!

LED Display Screen Price Check

Quick and easy: Enter your specifications and get a quote in one business day